BERTIM – Building Energy Renovation through TImber prefabricated Modules

Building Characteristics

Building type

Type of ownership

Climate

Age Class

Cost Benefit Indicators

Embedded Technologies

Envelope

HVAC

Renewables

Energy management

Technology readiness

system prototype demonstration in operational environment

Description

The traditional building energy renovation is characterised by on time consuming processes, where most of the work is done on-site, and based on very manual processes with barely connection between stages of the renovation.

BERTIM proposes a holistic building energy renovation approach encompassing prefabricated timber modules for building renovation supported by a digital tool named RenoBIM for a very efficient procedure from the data gathering, design, manufatring, to the installation phase.

The timber solution provides the opportunity to renovate buildings improving energy performance and the RenoBIM tool, based in a digital data flow in BIM, enables reduction of renovation operation time and make more efficient the renovation process.

The prefabricated timber solutions provide the opportunity to renovate, improving building energy performance, air quality, aesthetics, comfort, and property value at the same time, while ensuring low intrusiveness during renovation works. The development is based on timber high energy performance prefabricated modules for energy rehabilitation to ensure important building primary energy consumption reduction through high insulation properties. They also integrate windows, insulation materials, collective HVAC systems, renewable energy systems and energy supply systems.

Prefabricated modules integrate in the factory all the building components (new windows, balconies, pipes and ducts). In order to enable the integration with enough accuracy and effectiveness, a computer tool (RenoBIM) based in BIM is also being developed to implement the mass manufacturing methodology from design to manufacturing and allow a digital data flow among the involved stakeholders. The platform includes a methodology and support tools to capture a real building data (using laser scanning techniques) transferring it to a BIM-based Web3D environment and a building renovation project definition and communication with CNC manufacturing system, by means of the usage of BIM, minimising the risk of any possible pre-fabrication mistake.

The use of this prefabricated solution timber based for a deep energy retrofitting of the building envelope is firstly aimed at reducing in total buildings (primary) energy consumption by at least a factor of 2 with respect to the current situation, and a cost-level better than traditional renovation activities. In addition, it is expected a reduction in installation time by at least 30%, compared to a typical renovation process for the building type, ensuring also a low intrusiveness and with minor disturbances for users.

|

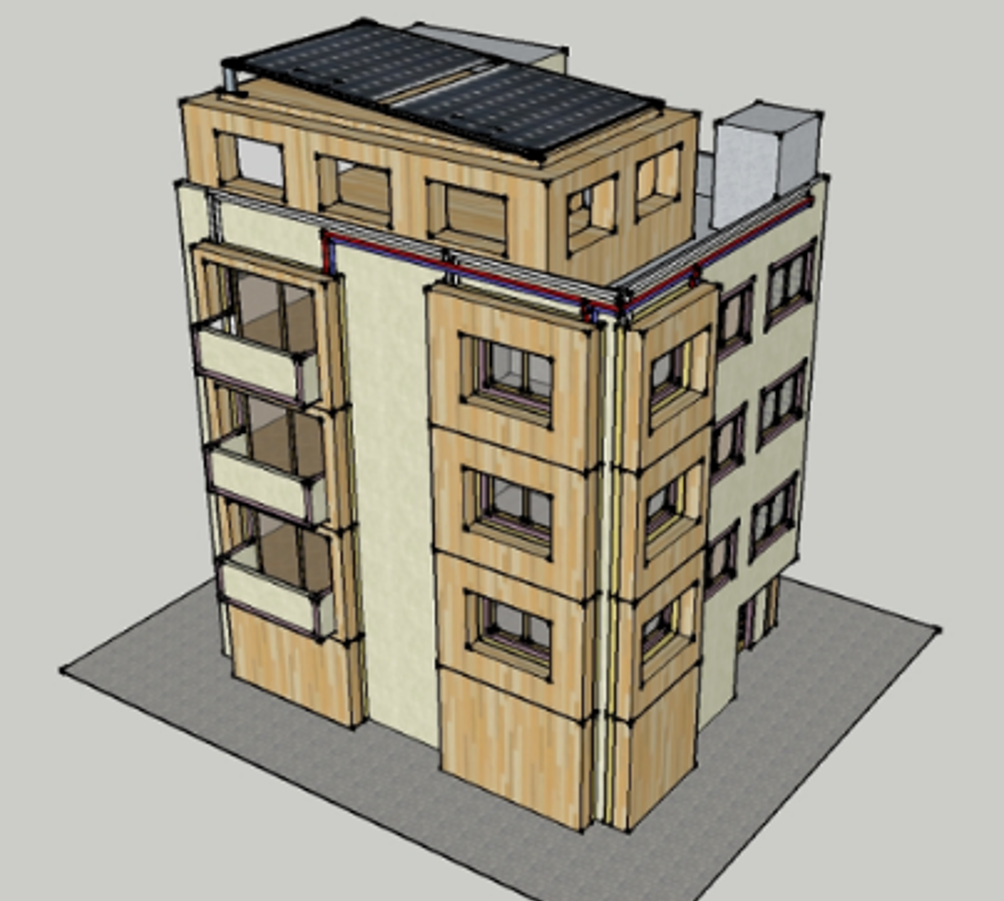

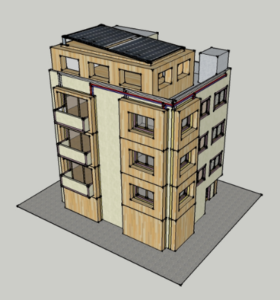

Concept of building renovation with BERTIM panels and 3D module on the roof

|

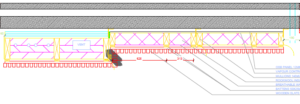

Sketch of the standard insulation panel finished with wood slash Sketch of the standard insulation panel finished with wood slash

3D timber module to be placed on the roof of the building increasing a new floor for residential purposes |

Section of the BERTIM modules. On the right part the basic panel and on the left the panel with embedded installation

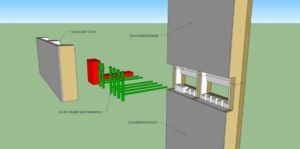

Sketch of a BERTIM module with embedded services where it is depicted the joints between conducts and pipes in the panel |

Design and implementation

Strenghts

- Easy and quick installation

- Low intrusiveness of the works

- Sustainability of the solution using local and recyclable materials (timber)

- Suitable solution for avoiding thermal bridges in energy retrofitting

Weaknesses

- Need of high accuracy on data gathering of façades to fully industrialize the process

- The modules with integrated services are not worthy in Northern countries (very cold climates)

- Commercialization plan still in

Opportunities

- Improvement of the manufacturing process will address more cost-efficient solution.

- Development of new technologies for data gathering will lead to major accuracy in measures of façade

- Construction in timber has very good acceptance in EU Northern countries

Threats

- Concurrence with other systems for energy retrofitting becoming more economic and popular

- Preference of other finishes rather than timber, due to the distrust created in terms of fire protection or durability

Example

Concrete examples followed by the project (supported by pictures, and schemes if requested)

At the moment, the timber panels only have been implemented in Tecnalia´s full scale experimental facility, KUBIK. This demonstrator involves the manufacturing, assembly and installation of BERTIM modules for validation in a real infrastructure. Moreover, this is the previous step before implementing the modules in an existing building, as it is planned in the demonstrators of Charité sur Loire (France) and Langshyttan (Sweden)

Installation of BERTIM modules in the experimental building KUBIK, on a flexible insulation layer placed to adjust the panels to the irregularities of the faced |

Detail of covers removed in order to show the services connection between panels

|

Overall view about the Experimental building KUBIK, where a façade has been renovated with BERTIM panels

|

Detail of the connection between services (HVAC systems) in the panels overlap.

Detail of the connection between services (HVAC systems) in the panels overlap.