iNSPiRe Kit – Wooden frame envelope module incorporating ducts and air-to-air heat pump

Building Characteristics

Building type

Type of ownership

Climate

Age Class

Cost Benefit Indicators

Embedded Technologies

Envelope

HVAC

Renewables

Energy management

Technology readiness

system complete and qualified

Description

This package, developed in the framework of the iNSPiRe project (funded by the European Community’s Seventh Framework Programme), includes:

- A prefabricated timber façade with windows

- A micro Heat Pump

- A mechanical ventilation system with heat recovery (MHVR)

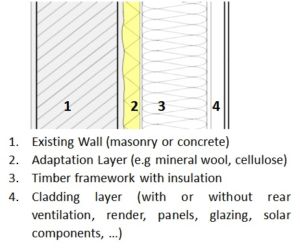

The prefabricated timber framed façade elements comprise timber, cellulose insulation, OSB (Oriented Strand Board), timber soft fibre board and different sorts of cladding. Windows, shading or other elements can also be prefabricated.

The prefabrication enables the industrialisation of the manufacturing process, and reduce the duration of on-site works.

The prefabricated façade is combined with a system which delivers a MVHR (mechanical ventilation with heat recovery), minimising where possible the installation of ducts inside the dwelling that remains occupied during the retrofit.

Parts of the ventilation system installed in the wall during prefabrication (Source inspirefp7.eu Credits Gumpp & Maier GmbH)

Design and implementation

Strenghts

- Precise prefabrication technique off-site and high quality due to a controlledproduction process

- Integrated solution, with pre-installed windows and HVAC devices

- Fast mounting process with little disturbance of the inhabitants.

- No weather downtime for on-site works

- Ecological performance with high CO2 storing capacity due to Wood utilisation, better LCA than polystyrene-based ETICS

Weaknesses

- Exigent logistics and planning process

- Thickness of additional layer

- Treatment of interstices between 2 panels

- The mounting of prefabricated modules is a new construction process and needs experience to be practised

Opportunities

- Integration and extensions of additional building elements, such as windows, balconies/loggias, HVAC devices, plumbing, electric cables.

- Incentives and subsidies (bonus for ecological materials)

- Creates regional added value with local sourcing, production and installation

Threats

- Fire regulations in multi-storey buildings > 6 floors

- Reduced application for historical buildings.

- Upfront cost higher than solutions such as ETICS which the procuts is erroneously compared to

Example

iNSPIRe – Ludwisburg

Karl-Dieter-Str. 24, 71636 Ludwigsburg

Completion: 2016

The demonstration building in Ludwigsburg has been chosen by the project iNSPIRe because it represents a widely used building typology during the middle of the 20th century, which now is reaching the end of its lifetime and needs to be renovated. The building is property of the Wohnungsbau Ludwigsburg GmbH, a housing association owned by the city of Ludwigsburg, who have also co-funded the retrofit of the building.

Timber elements were prefabricated in the factory of Gumpp & Maier in Binswangen (DE) and transported to the building site on semitrailers. Each one of the cassette elements was built to cover a complete side of each apartment, with total dimensions of maximum 2.95 m height, and 12.20 length and with a weight of up to 2.5 tons. They were designed to maximise the level of prefabrication in order to reduce work on site, and to achieve a weather safe envelope as fast as possible. The off-site manufacture included closed insulated cassettes, painted timber cladding, windows, external chills and reveals, venetian blinds and steel weather profiles. The U value achieved by this wall build up, including the existing wall is 0.10 W/m²K. The roof construction achieves 0.13 W/m²K.

The renovation of the building services (e.g. ventilation ducts) has been integrated in the construction process to make it in a whole more efficient. A mechanical ventilation with heat recovery (MVHR) unit with a micro heat pump has also been integrated in the prefabricated timber frame façade.

Finally, the integration of a large solar thermal collector installed on the roof, with a size of 11.3 m², was designed to maximise the degree of prefabrication and to develop a solution, which is aesthetically integrated to the roof surface. For that purpose, an in-roof solution was implemented, where the timber construction was reduced in thickness, in order to level it down with the rest of the roof.

All together the renovation took 3 months of construction time on site and two apartments were inhabited throughout all this time.

More information here: