GAP Solutions

Building Characteristics

Building type

Type of ownership

Climate

Age Class

Cost Benefit Indicators

Embedded Technologies

Envelope

HVAC

Renewables

Energy management

Technology readiness

actual system proven in operational environment (with competitive manufacturing)

Description

The GAP solutions is a complete solution developed around three core business, GAP Engineering, Gap systems and GAP Services.

GAP1 engineering

GAP1 engineering stands for close collaboration of architects, planners and executors as well as for the careful coordination of building-physical and energetic conditions. GAP engineers are the competent interlocutors that accompanies the client through all realization phases, from conception to implementation. This combination ensures integrated processes and smooth work flows. Based on a comprehensive collection of facts, an energy-optimized construction and management concept are developed in order to be implemented precisely and efficiently. In doing so, solid craftsmanship is combined with industrial production and the special GAP system.

GAP2 Systems

The intelligent GAP facade solutions practically don’t allow any heat loss – the interaction of light, wood and air eliminate thermal bridges and increases the hygrothermal and acoustic comfort. The GAP system has been developed in collaboration with leading universities and research institutions and extensively tested.

The optimized house envelope also allows for optimization of the house technology. Simple and decentralized systems are cost effective in investment and maintenance. The coordinated complete system consisting of facade and building technology sets economical and ecological standards. Based on the interaction of the components, GAP2 systems focuses on sustainability and renewable energy.

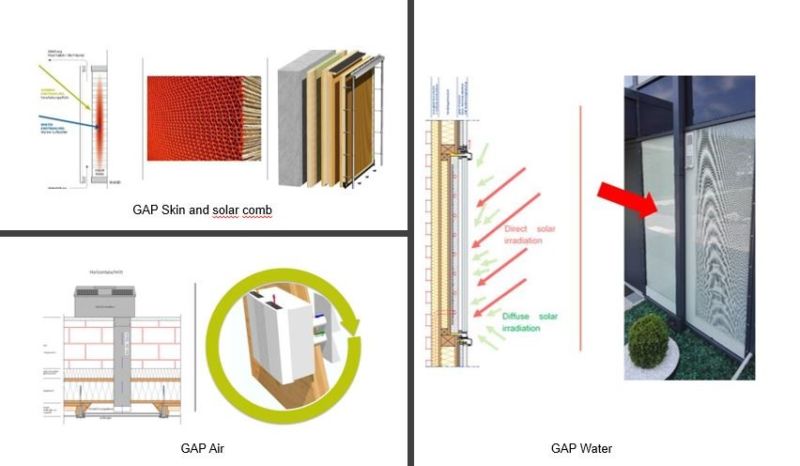

- GAP Skin

The building is enclosed by a tempered air cushion – This buffer zone is a climate regulator and ensures a pleasant room climate during all seasons.

First grade materials ensure long-term quality. GAP glass facades are durable and weatherproof, allowing a drastical reduction of maintenance and operating costs. The evenly warm facade, which is also open to vapour diffusion, ensures mould-free rooms and balances out thermal faults in the building envelope. It is composed as follows:

- Wood construction + insulating material : ≥ 60 mm

- Framework wall in solid wood+ insulating material : 151 mm

- Wood panel (DFP): 19 mm

- GAP-Honeycomb panel in cellulose. 30 mm

- Air gap (slightly ventilated): 29 mm

- ESG float glass panel: 6 mm

- Attaching parts in aluminium

- GAP Air

GAP Air is a decentralized ventilmation system based on heat recovery. The ventilation element is embedded in the facade; customized object solutions are also provided. The cost benefit compared with central systems is up to 60% depending on the construction. Independent of central building technology, hygienic and easy to service, they require no regulation expenditure.

- GAP water

Based on individual project requirements, GAP:water offers customized solutions for hot-water generation and heat recovery. The main principle is the prevention of energy loss. The supply is provided by the facade, at maximum decentralization. GAP:water uses existing waste water heat and focuses on eliminating long lines resulting in heat loss. Based on individual requirements, concrete storage absorbers, loss-free hot-water distribution, heat recovery and photovoltaic are combined.

Maintenance-free and requires no regulation expenditure.

GAP3 Services

Finally, the implementation of the solutions, including installation – and throughout the entire utilization cycle is ensured. Production, machines and installation are provided. Industrial production and installations guarantee efficiency, precision and safety of systems and operations.

Source ©GAP Solutions GmbH

Design and implementation

Strenghts

- Low-tech and passive solar system

- Integrated processes

- Interaction of all components

- Active

- Multifunctional

- Quick installation and habitability of the building during renovation

- Improvement of indoor environment quality and comfort

- Minimized operating and maintenance costs

- Unique selling proposition / patent protection

Weaknesses

- Large-scale program needed

- Dependant of a relevant network of professionals

- Increased investment costs, but clear advantages with LCC`s

Opportunities

- Industrial production (cost-effective)

- Solutions to tackle fuel poverty (Scarce use of resources)

- Environmental consciousness

- The goals of the UNO Agenda and Misson 2030 can be achieved at any time.

- Adaptable to various buildings, climate and situations (customer-oriented)

- One partner taking full responsibility – for carefree processing

- Optimum life cycle costs

- Financability solely through energy savings or energy cost savings

- Decentralized energy supply & blackout security

Threats

- There are no competitors, except those of the classic systems

- Lack of framework for standardisation

- Innovative products insurances for implementation

- Certification costs

Example

Background

The renovation of the Dieselweg residential area, located in the south of Graz (Styria) was perfomed in 2009.

Two out of the six building blocks (gross area around 9 000 m²) were renovated under the GIWOG Gemeinnützige Industrie Wohnungs AG and the GAP-solution GmbH management.

Since the time of construction (1950-1960s) no improvement measures have been carried out. Therefore the building stock showed a very energy inefficient and poor situation. Due to poor structural condition and energy performance the heating costs were high and the thermal comfort and living quality were low. But the most challenging circumstance was the fact that it was considered to be impossible to resettle the tenants during constructions works.

Renovation solutions

The renovation concept for the “Dieselweg” was mainly based on following aspects:

- The essential improvement of the thermal envelope with prefabricated façade modules.

- The integration of a series of components into the prefabricated façade module system like windows, shading appliances,ventilation devices and solar thermal collectors.

- The implementation of a new and innovative solar-active energy concept. This concept lead to a significant reduction of the heat demand (about 90%) and the greenhouse gas emissions. Furthermore the decrease of running costs for space-heating and DHW-preparation spared an increase of rents. Moreover the housing association predicted lower resulting monthly charges for the tenants.

The basic principle of the solar façade is the solar comb. it is arranged on the OSB board, covered by a glass panel. Inbetween is a rear ventilated air space. Sunlight falls through the glass and leads to an increased temperature in the airspace and the solar comb. This increased temperatures lowers the difference between inside and outside temperature in winter and leads therefore to reduced heat losses and an improved effective U-value (compared to the static U-value).

The ducts for supply air and exhaust air are integrated in the module. The ventilation systems are positioned beside the windows – on the outside the ducts are covered with opaque glass panels.

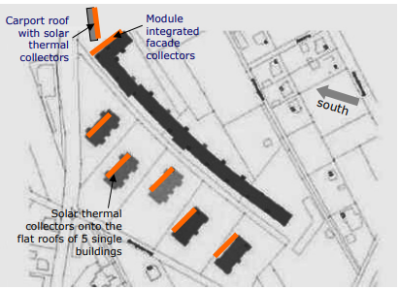

Core of the innovative energy concept is the integration of solar thermal collectors to a great extend. The entire plant provides a collector area of 3m2 per apartment.

Heat storage tanks (5 m3) were installed in the basement and supplied by the solar thermal plant and a ground water heat pump.

Regarding this example, this project was realized more than 10 years ago. Today, a more decentralized and more reduced in technology approach can be applied in those kind of refurbichment solution in order to achieve “Plus-energy-Buildings” standards.

Running costs

Heating:

- Before renovation about € 2.00 m2 net floor area / month (calculated for an apartment heated by electric heating device)

- After renovation about € 0.11 m2 net floor area / month

DHW:

- Before renovation about € 0.40 m2 net floor area / month

- After renovation about € 0.10 m2 net floor area / month

Sequence of prefabrication procedure in the fabrication hall (Source IEA ECBCS Annex 50, GAP-Solution GmbH)

Installation of the prefabricated facade (©GAP solutions GmbH)

Site plan showing the solar thermal collector areas and the position of the heat storage tanks (Source IEA ECBCS Annex 50, Hohensinn ZT GmbH)

Related Case Study

Graz district

The renovation of the Dieselweg residential area, located in the south of Graz (Austria) was supported by the Austrian system of public housing aid, by additional research funds and by a special support of the governor of environmental affairs of Styria and by the non-profit organization of the GIWOG corporation.

Due to the fact that since the time of construction (1960s) no improvement measures have been carried out, the building stock showed a very energy inefficient and poor situation, with high heating costs and low quality thermal comfort and living.

At this showcase project for the high-performance renovation of a large-volume residential building, the passive house standard was achieved and the heating costs significantly decreased. CO2 emissions were also reduced by the use of renewable energy sources, e.g. solar thermal energy. Prefabricated large-scale façade modules with integrated windows and ventilation systems were used. In this way, an essential increase of the thermal and user comfort was achieved and the indoor environment was improved.