My profile

The renovation of Sneinton district was implemented in the framework of the H2020 funded REMOURBAN project (http:// http://www.remourban.eu/).

The project included the renovation of a variety of property typologies in Nottingham within the Sneinton area ranging from single-family to multi-family houses, and in age, from 1900 to the 70s. A large number of the properties (65%) in the area are social housing, owned by Nottingham City Council (public owner) and managed on their behalf by Nottingham City Homes. The project included both energy efficiency measures (mainly walls insulation) and the connection to district heating.

As this project was also part of the Energiesprong UK programme, an “Energiesprong-type” package (with prefabricated façade) has been implemented.

Regarding financing, each home owner/private landlord received a Remourban grant towards the work, leaving a contribution of between 1.400€ and 2.536€ (£1,260 – £2,280) to pay, depending on the property type. Without the grant, this home improvement would normally cost upwards of 8.900€ (£8,000).

The renovation of this residential building locate in Munich was implemented in the framework of the FP7 funded E2Rebuild project (http://www.e2rebuild.eu/).

The residential multi-storey building in the suburb of Sendling, Munich (Germany), owned by the public housing company GWG München and made up of uniform standard concrete brick blocks, was built in the post-war decade of the 1950s. The building has been fully retrofitted, including the replacement of the attic by an additional floor to create more rental space, increasing the Net Dwelling Area to 3.323 m2 (originally 2.012 m2, + 65 %, phase 2 + 155 %).

The main refurbishment actions performed included:

- TES Energy Facades, prefabricated with cellulose insulation added to existing outside walls, U-wall 0,12 W/m²K. Painted timber windows with triple glazing, U-window 0,9 W/m²K and outside solar control fixtures.

- The roof consists of visible timber beam construction, highly insulated with U-roof 0.11 W/m²K and greening on top. Accessible terraces and thermal solar collectors occupy the whole surface area.

- Central (residual) heating system (CHP combined heat + power, planned before: wood pellet boiler plant), two central heat storage tanks (20 m3) with dual piping system and fresh hot water substations.

- Space heating and domestic hot water assisted by two solar thermal collector systems (208 m²) over green roofs, (solar photovoltaic system proportionally provided over green roofs of building phase 2).

- Controlled ventilation of flats (fresh and waste air) with heat recovery, distributed system for flats (facilitated fire safety, lower costs), centralised in the new building for the district office and habitations.

The renovation plan for the primary school “St. Kiril and Methodius” was developed in the framework of the EuroPHit project (https://europhit.eu/) co-funded by the Intelligent Energy Europe Programme of the European Union. The renovation plan follows a Step-by-Step Business Model approach, aiming at achieving the EnerPhit standard, based on the Passive House principles.

The building was constructed in 1970. It has a concrete structure with external brick walls and a concrete flat double ventilated roof, and no insultaion was installed. Since 2013, the school has been connected to the central gas heating.

The renovation work included improvement of the building envelope with new thermal insulation on the roofs, on the external walls, on the ground walls and the slabs on the ground. Furhtermore, the windows were exchanged when their lifespan was over.

The project proposed the following refurbishment steps:

- STEP 1- roof insulation – placing 30 cm. glass wool insulation on the top of the lower slab of the ventilated double roof.

- STEP 2 – mounting 20 cm EPS with graphite insulation on the walls, reduction of the radiator dimensions, improving the airtightness layer, implementation of the ventilation with heat recovery systems.

- STEP 3 – External underground wall insulation, perimeter insulation, insulation above the ground floor slab in the gym.

- STEP 5 – Replacement of windows: the PVC windows will be replaced in 10 years, when they will be 20 years old. The aluminum windows will be replaced in 20 years, when they will be 30 years old.

- STEP 6 – Implementation of Renewable Energy Sources (Photovoltaic panels)

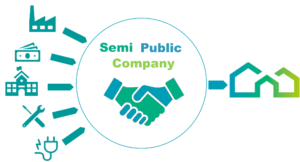

The collaborative model presented hereafter differs from the traditional PPP model and presents the model of One Stop Shops provided by semi-public entities, where local authorities and private companies join forces to provide sustainable OSS structures – so called renovation platforms – to support the residential renovation market.

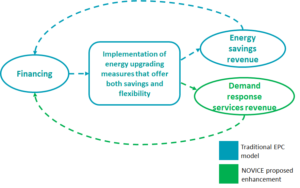

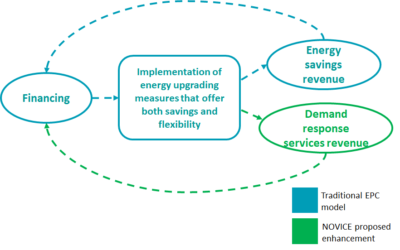

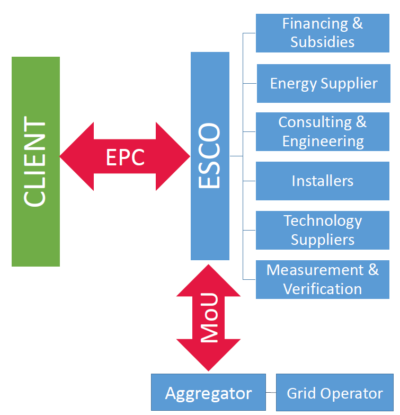

The Enhanced Energy Performance Contracting (EPC) model, proposed by NOVICE project, consists to generate revenues from Energy Savings, as in the classic EPC model, but also to generate revenues from Demand Response Services.

Demand response is a way of shifting or reducing electricity usage during peak periods. Indeed, when electricity demand exceeds supply on the grid, clients’ electrical asset consumption can be adjusted by using aggregator technology. Thanks to this shift, power returns to the grid and the supply and demand balance is restored in a cost effective and green way. Also, the clients earn revenues simply for participating and being available.

Demand response is a way of shifting or reducing electricity usage during peak periods. Indeed, when electricity demand exceeds supply on the grid, clients’ electrical asset consumption can be adjusted by using aggregator technology. Thanks to this shift, power returns to the grid and the supply and demand balance is restored in a cost effective and green way. Also, the clients earn revenues simply for participating and being available.

In the Enhanced EPC model, the ESCOs remain the single point of contact for all measures but uses the services of a demand response aggregator to provide services to the grid. A Memorandum of Understanding (MoU) governs the relationship between ESCO and Aggregator.

Market readiness for Enhanced EPC is varying across European countries.

Some of them, like France or UK, have well developed or growing ESCO markets and several open DR markets with regulation that encourages aggregators to participate. Other countries (Belgium, Germany, Finland…) have either an advanced ESCO or an open DR market but strict regulations that limit the ability of aggregators to participate. Finally, some EU countries like Italy or Spain have immature ESCO and closed DR markets (or do not legally allow aggregation).

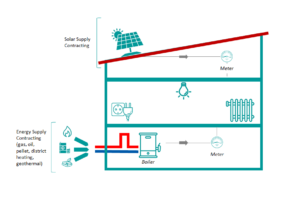

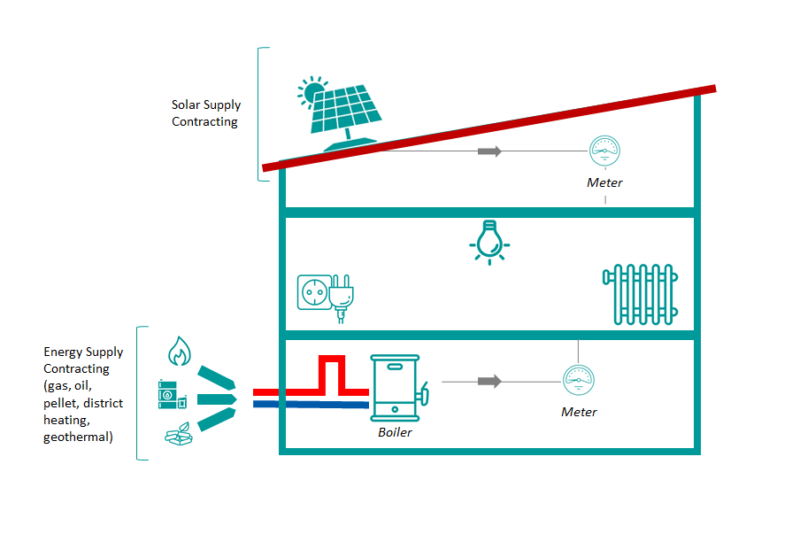

The Energy Supply Contracting (ESC) business model is a proven model to implement efficient supply (from fossil and/or renewable sources) in new and existing buildings of the public, industrial, commercial and large residential sectors. The goal is to bring a reduction of final energy demand, although efficiency gains are usually limited to the energy supply system.

Indeed, under an ESC model, an Energy Service Company (ESCO) is only remunerated for the useful energy output, i.e. it supplies useful energy, such as electricity, heat, or steam under a long-term contract to a building owner or building user. It is therefore in the interest of the ESCO to reduce the final energy demand. The output is measured and verified in Megawatt hours delivered. ESC models run under long-term contracts of typically ten to fifteen years, depending on the technical lifetime of the equipment deployed.

Extended project terms or building cost allowances allow to include measures with longer payback times, like facades with integrated PV modules or entire building envelopes. The building owner has the opportunity to outsource technical and economic risks related to energy supply activities (including planning, installation, operation, maintenance and financing of equipment for heating, cooling or electricity generation) to a professional party and to buy services instead of individual components. ESC often includes supply of final energy through the ESCO.

As the ESCO’s remuneration is performance based and depends on the useful energy output delivered, the ESC model provides an incentive to increase the efficiency of the energy conversion and to reduce primary energy demand. Contract covers the outcome and all costs of the services, as well as the commercial, technical and operational risks of the project. ESC may accelerate the uptake of Renewable Energy Technologies (RET) if they are cost competitive over the lifecycle of the project because ESCOs have an inherent interest to reduce life-cycle costs.

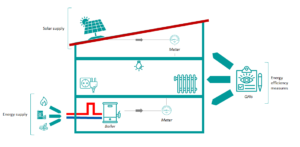

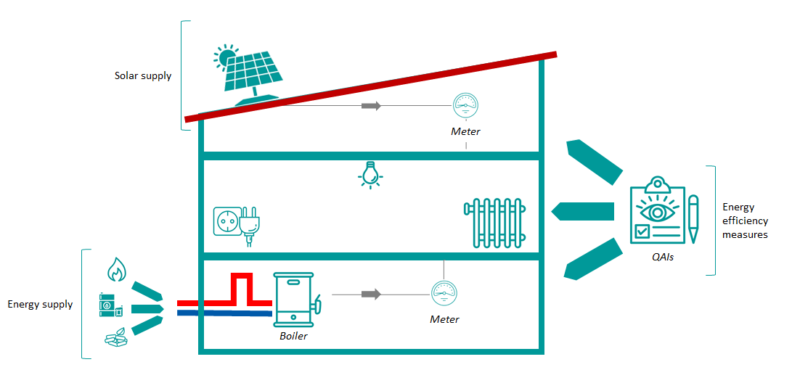

The Integrated Energy Contracting (IEC) business model is a hybrid of Energy Supply Contracting (ESC) and Energy Performance Contracting (EPC) which combines two objectives:

- Reduction of energy demand through the implementation of energy efficiency measures in the areas of building technology (HVAC, lighting), building envelope and user behaviour;

- Efficient supply of the remaining useful energy demand, preferably from renewable energy sources.

It is methodologically based on the ESC model and is supplemented by a “deemed energy savings” approach regarding energy efficiency measures. Compared to standard ESC model, IEC model extends the range of services to the energy and emission savings potential for the whole building, with support of Quality Assurance Instruments (QAIs).

Deemed savings are a specific approach to estimate energy and demand savings, used with programs targeting simple efficiency measures with well–known and consistent performance characteristics. Basically, this method involves multiplying the number of installed measures by an estimated (or deemed) savings per measure, which is derived from historical evaluations. This approach replace the potentially complex and costly measurement of energy savings undertaken in the EPC business model. Therefore, IEC reduces transaction costs, especially for small projects.

As compared to standard ESC, the range of services in IEC model is extended to the overall building or commercial enterprise, so the offer is not limited to heat supply. Instead, the model is intended to be used for all energy carriers such as heat and electricity, but also other consumption media such as water or compressed air.

As with ESC and EPC, the IEC business model offers the building owner the choice to outsource technical and economic risks, associated with the implementation of Renewable Energy Technologies (RET) and energy efficiency measures, to a professional third party and buy services instead of individual components. IEC may be particularly suitable to combine supply from renewable sources with energy conservation measures, and thus accelerate RET adoption.

Basically, the IEC business model benefits from the ESC with similar price components, and it is supplemented with a flat rate price for the energy efficiency measures. Individual QAIs for the installed energy efficiency measures secure the functionality and performance of the measures, but not their exact quantitative outcome over the entire project cycle compared to EPC tools. The objective is to simplify the business model and to reduce (transaction) cost by balancing measurement and verification cost and accuracy. Appropriate QAI’s need to be defined for each energy efficiency measure, e.g. a one-time performance measurement for a new street lighting or a one-time thermographic analysis for verifying the quality of a refurbished building envelope. These QAIs replace the annual measurement and verification of the EPC savings guarantee.

The Add-on Business Model is a renovation strategy corresponding to the construction of one (or a set of) additional building unit(s) – like aside or façade additions, rooftop “vertical” extensions or even a new side-building construction – that are added to the existing building when performing renovation works.

When combined with the adoption of EE or RET measures, volume additions are interesting types of intervention since they instantly produce new,  commercially valuable dwelling areas which could compensate the costs of energy-optimisation (thanks to the sale or the rent of the new dwellings).

commercially valuable dwelling areas which could compensate the costs of energy-optimisation (thanks to the sale or the rent of the new dwellings).

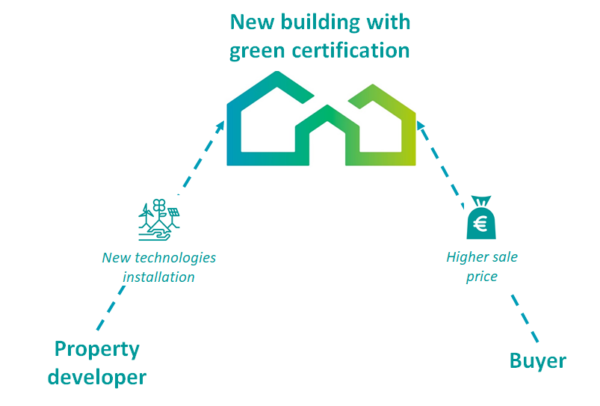

Green building certification systems assess a building’s performance based on environmental and wider sustainability criteria and provide the evidence that building procures a certain sustainability standard. Green certification can stimulate investments in renewable technologies, even when they are not cost-effective. However, it is generally efficient in niche markets because such certification is on a voluntary based.

In this business model a property developer or architect designs and builds buildings certified according to a voluntary green certification scheme, expecting to realize a sales/rent price premium compared to conventional buildings. This is frequently the case in the North American and some Asian markets.

This premium should compensate for the additional costs related to the green features of the building, and for the costs of the certification.

Drivers for an increasing demand for certified buildings include:

- Corporate Social Responsibility (CSR): green buildings are part of their green image;

- Reducing operating costs of green buildings

- Enhancing levels of comfort for building users, which in commercial buildings may lead to higher productivity and less sick leave;

- Regulation which mandates green certification, for example for public buildings, and turns voluntary schemes into mandatory ones.

Most green building certification systems cover a range of environmental and broader sustainability criteria related to energy and water uses, indoor environment and materials used. Some systems also include criteria on functionality and comfort, economic questions and innovation. Normally, a building must fulfil most of the criteria set by the certification systems.

There are a variety of voluntary certification systems globally. The most widely used are the U.S. Green Building Council’s LEED standards and the UK based ‘Building Research Establishment Environmental Assessment’ (BREEAM). There are also schemes which focus exclusively on energy related criteria, e.g. the U.S. and Canadian Energy Star label for buildings, the German ‘Passive house’ standard, the French ‘Haute Qualité Environnementale’ (HQE) stardard and the Swiss ‘Minergie’ standard.

In addition to certification systems, there are also building rating systems, which do not issue a formal certificate. These rating systems support project developers by setting clear standards on what constitutes a green building. As rating a building is cheaper than undergoing a formal certification process, rating systems are frequently used for residential buildings.

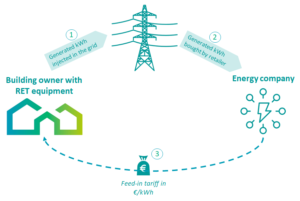

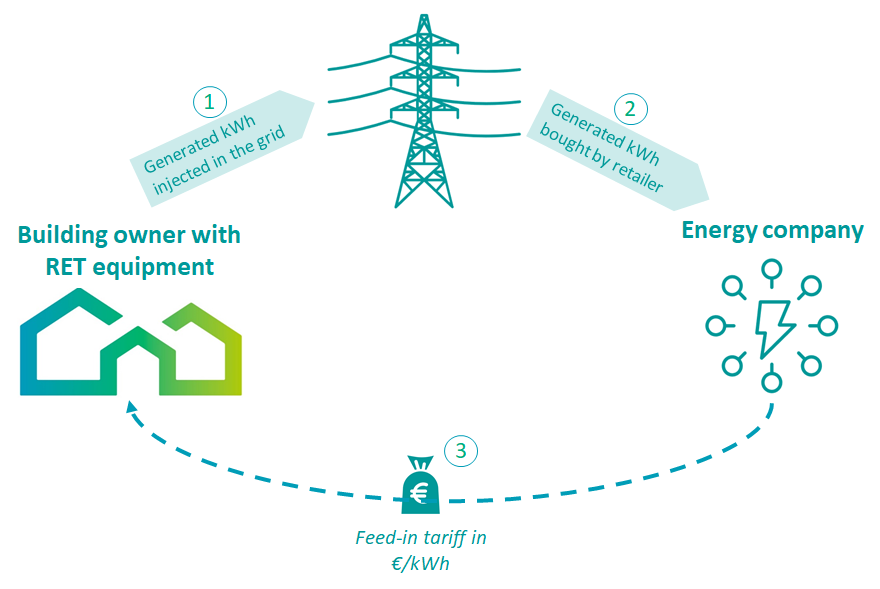

A feed-in remuneration is a support scheme allowing the producer of renewable energy to receive a direct payment per unit of energy produced. This feed-in remuneration can be a tariff, like a preferential price covering the full generation costs, or a premium, which provides a ‘bonus’ for the producer to cover the financial gap between the generation costs of using renewable energy versus using conventional (fossil) energy.

Feed-in schemes are very efficient to increase the deployment of RET, as they cover the higher cost of RET by compensating the owner with a higher price for the renewable generation. A feed-in remuneration scheme creates opportunities for business cases as it can cover the financial gap between RET and conventional technologies. Feed-in tariffs or feed-in premiums for electricity from renewable sources are the most common, but also exist for renewable heat.

Through a feed-in remuneration scheme the producer of renewable energy receives a direct payment per unit of energy produced. A feed-in scheme guarantees access to a predictable and long-term revenue stream, which can serve as a stable basis for a business model.

In addition to the tariff scheme, in which the producer gets a fixed price for the supply of energy, and the premium scheme, in which the producer gets a premium in addition to income from selling the energy on the market, hybrid forms are also possible. In these, the premium complements the income from the market, to jointly cover the generation costs. Producer gets a fixed amount, but from two different sources. This hybrid form is similar to a feed-in tariff for the investors, but it has different consequences for government expenses. A feed-in scheme typically publishes rates per energy unit for eligible production (e.g. in €/GJ or €/kWh). If a producer is eligible, a contract (or agreement) can be obtained from the government that allows the producer to claim the specific tariff (or premium) for every unit produced. This agreement fixes the conditions and levels of the tariff, typically 8-20 years depending on the technology. So once an agreement is entered, this is virtually risk free. Some feed-in schemes only cover energy that is delivered to the grid, whereas other schemes also cover auto-production (using generated energy for own purposes).

Feed-in schemes do not look at specific projects and real costs, but instead use cost estimates per category. As a result, within a category some initiatives may be economically viable whereas others are not. To build a viable business model based on a feed-in scheme, the investor has to undertake a careful assessment of the project economics taking into consideration e.g. climate conditions for solar PV or heat pumps, technology costs, and fuel prices, e.g. prices of biomass for a biomass boiler.

In the case of building refurbishment, feed-in schemes can be used by households and small/medium enterprises who want to generate their own energy using renewable sources (e.g. solar-PV or biomass heating). Such business models by households or SMEs can be focused on production for own use, or for the sale of energy to the grid. Feed-in schemes typically differentiate in categories by size of the installation, technology and fuel used. The level of remuneration is based on the category specific generation costs (usually estimated through the size of the installation, for instance installed capacity in kWp for PV), but the actual payment is based on production (e.g. kWh of electricity).